This toolset augments XA/MRP with value-added extensions and business information to help planners support the review and execution of exceptions in MRP, as well as help with managing inventory, and support a more efficient process in all activity around reviewing, releasing, changing and cancelling recommendations. This toolset helps peg source of demand quickly, and can support project type planning very effectively for complex equipment manufacturers and discrete demand. All key pieces of information related to planning, including help with shortages are provided by this toolset. Custom work benches are provided to support individualized process flow for buyers and manufacturing planners, customized around special needs. For example a planning fabricated work bench can be set up to maximize your planning decisions around common raw material. Other decisions needed to support smart planning and buying is provided by summarizing overall usage over the past 12 months, or beyond is displayed in a user friendly card set. Demand can be identified easily for forecast vs. customer order, or safety stock.

This product evolved over 14 years of working with planners and buyers at XA customers to leverage the Power of XA/IDF and the GUI framework. Typically, this tool is supported with a training class to customize the execution of the planning exceptions to your organization and assist with a streamlined transition.

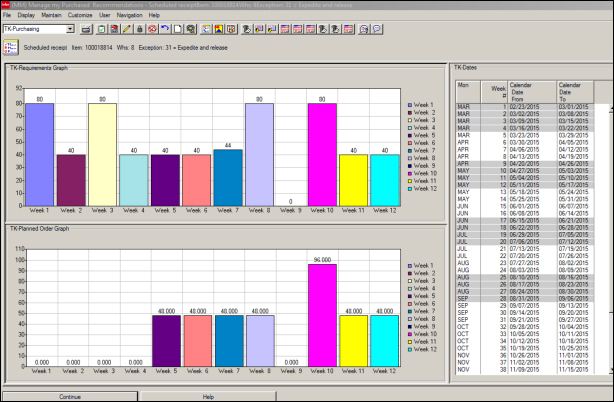

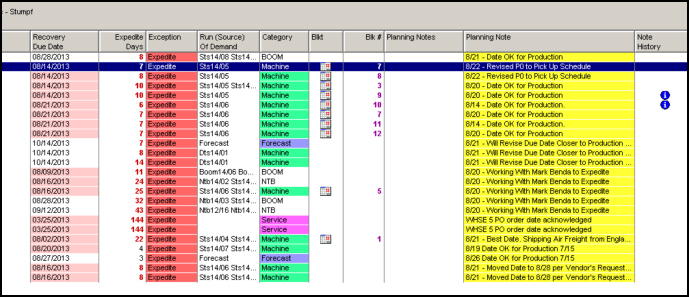

Order Recommendations showing extended fields and visual aids.

Requirements and usage shown in user friendly graphs and summaries that help make decisions quickly.

Request More Information